ELECTROMECHANICAL

Pulsarlube EX

-

125

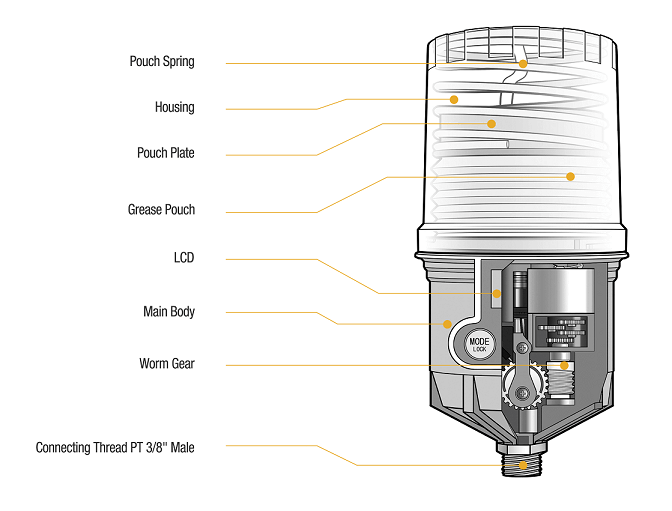

Pulsarlube EX consists of a vertical self-priming pump, microprocessor control system, and large LCD display. This product is ideal for applications where: considerable back pressure in lube line exists, a precise lubrication is required, or a disposable gas type lubricator is not economical.

The circuits and parts of the Pulsarlube EX are designed based on the energy limitation concept by adopting a non-sparking, explosion-proof structure that keeps an electrical device from sparking an explosive gas whether it is working under normal or certain abnormal condition.

FEATURES

ATEX

Specifically designed for places where Class I, Division II, Group C & D certification is required

Service Pack

Substantial savings from the use of replaceable grease pouches and battery packs

LCD

Easy to program with built-in LCD and simple button controls

PRODUCT INFO

CROSS SECTION

SPEC & CERTIFICATIONS

| SPEC | Description |

|---|---|

| Grease Pouch Capacity | 125ml/250ml (replaceable) |

| Power Supply | DC 4.5V Battery Pack |

| Operating Pressure | Max. 15bar (218psi) |

| Operating Temperature | -15˚C~60˚C (5˚F~140˚F) |

| Dispensing Periods | 1, 2, 3, 6, 12 month & H (15 days) |

| Remote Installation | Max. 3m (10ft) with O.D. Ø6 tube (Direct mount is preferable) |

| Multi-Point Installation | N/A |

| Packaging | 10 Units/Case |

| IP Code | IP54 |

| Certifications | ATEX, KCs, UL, CE |

| Certification | Description | ||

|---|---|---|---|

| IP Code | IP54 | ||

| ATEX | Ⅱ 3 G / Ex nL ⅡB T5 | ||

| UL | Cl.Ⅰ, Div. 2, Gps C, D | ||

| KCs | Ex nL ⅡB T5 | ||

| CE / Etc. | CE (CoC) | ||

| Certification | UL | ATEX | KTL |

| Rating | Class l Division 2 Groups C.D | Ex nL IIB T5 | Ex nL IIB T5 |

| Maximum Surface Temperature | T6 (85˚C) | T5 (100˚C) | T5 (100˚C) |

| Enclosure Protection Indices | - | IP54 | IP54 |

| Classification Of Hazardous Locations | Cl l Div2 | Zone2(gas) | - |

| Certificate Number | E304815 | LCIE 07 ATEX 6100X | 12-KB2BO-0279X |

The Pulsarlube EX is tested and certified by UL(USA), ATEX(Europe) and KTL(Korea). Refer to the table on the left when Certification for use is hazardous locations should be considered.

WARNING

– Explosion Hazard

– Do not remove or replace batteries unless power has been disconnected or the area is known to be free

of ignitable concentrations of flammable gases or vapors.

– This equipment is suitable for use in Hazardous Locations.

- SUBSTITUTION OF MOTOR AND REED SWITCH MAY IMPAIR SUITABILITY FOR DIVISION 2.

| Reference Designation | Description | Type of Protection |

|---|---|---|

| M1 | Motor | Non-incendive Circuit |

| SW4 | Reed Switch | Non-incendive Circuit |

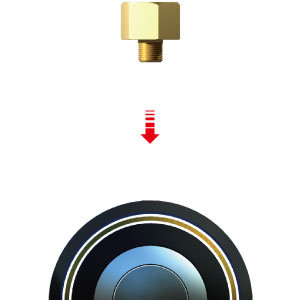

INSTALLATIONS

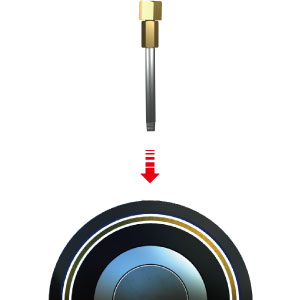

| Part No. | Description |

|---|---|

| A001 | Reducer, 3/8"F x 1/4"M Adaptor (Brass) |

| A002 | Reducer, 3/8"F x 1/8"M Adaptor (Brass) |

| A002-S | Reducer, 3/8"F x 1/8"M Adaptor (Brass) |

| Part No. | Description |

|---|---|

| A011 | Socket, 1/4"F x 1/4"F Adaptor (Brass) |

| A012 | Socket, 1/8"F x 1/8"F Adaptor (Brass) |

| Part No. | Description |

| A121 | Pipe,1/4”M x 1/4”M x 50mm (Steel) |

| A122 | Pipe,1/4”M x 1/4”M x 100mm (Steel) |

| A123 | Pipe,1/4”M x 1/4”M x 150mm (Steel) |

| A124 | Pipe,1/4”M x 1/4”M x 200mm (Steel) |

| Part No. | Description |

| A106 | Pipe, 1/8"M x 1/8"M x 50mm for divider block (Steel) |

| A107 | Pipe, 1/8"M x 1/8"M x 150mm for divider Pipe, 1/8"M x 1/8"M x 100mm for divider block (Steel) |

| A108 | Pipe, 1/8"M x 1/8"M x 150mm for divider block (Steel) |

| A109 | Pipe, 1/8"M x 1/8"M x 200mm for divider block (Steel) |

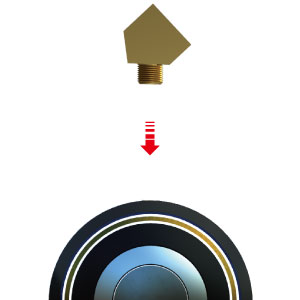

| Part No. | Description |

|---|---|

| A023 | 45° Elbow, 1/4”M x 1/4”F Adaptor (Brass) |

| A024 | 45° Elbow, 1/8”M x 1/8”F Adaptor (Brass) |

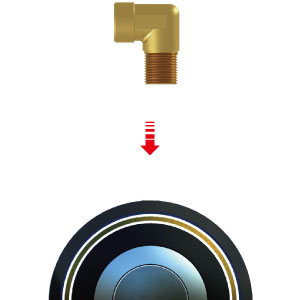

| Part No. | Description |

|---|---|

| A019 | 90° Elbow, 1/4”F x 1/4”F Adaptor (Brass) |

| A020 | 90° Elbow, 1/8”F x 1/8”F Adaptor (Brass) |

| A021 | 90° Elbow, 1/4”M x 1/4”F Adaptor (Brass) |

| A022 | 90° Elbow, 1/8”M x 1/8”F Adaptor (Brass) |

If the bearing lube point is NPT, use the thread converter (A243) to convert thread metric to inch for bearing zerk (USA only)

- All Parts should be assembled tightly with PTFE tape.

- For optimal performance with remote installation kits, using an NLGI #1 grade grease is recommended.

- If the bearing lube point is NPT, use the thread converter.

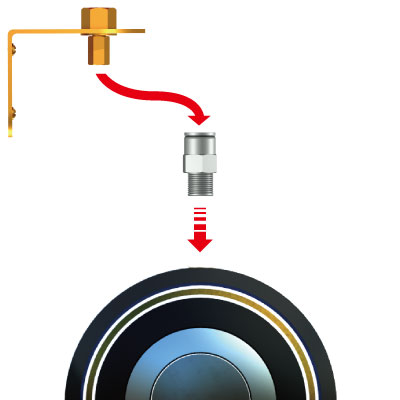

| Part No. | Description |

|---|---|

| A002 | Reducer, 3/8"F x 1/8"M Adaptor (Brass) |

| B002 | Mounting Bracket, “L”Shape |

| B051 | Self Drilling Screw, #8 x 20 |

| B057 | Washer |

| A012 | Socket, 1/8”F x 1/8”F Adaptor (Brass) |

| A240 | Tube Fitting, Push-In Type, PC6-PT1/8”M |

| A214-1 | Distribution Tubing, O.D. 1/4"(6mm) Nylon Tubing, 10ft Pre-filled with (Grease Type) |

| A243 | Thread Converter, PT1/8"F x NPT1/8"M (Brass) |

Note : For remote installation using a tube, use an 8mm O.D. (5/16″) tubing pre-filled with the same or compatible grease as the grease contained in the unit. Recommend using under short dispensing period settings due to powerful dispensing pressure.